Uncovering the science behind biocompatibility

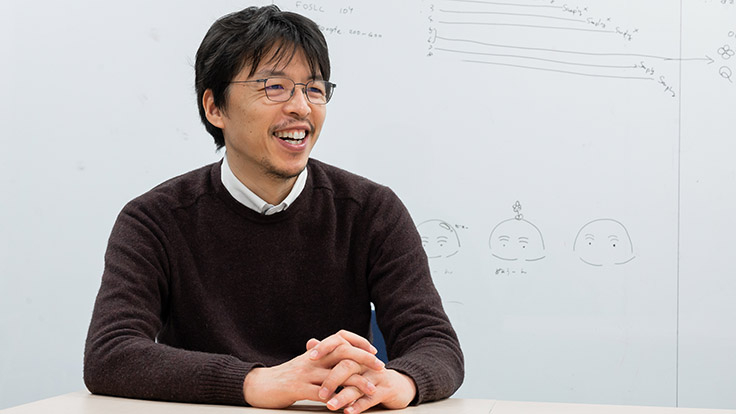

with Prof. Masaru Tanaka

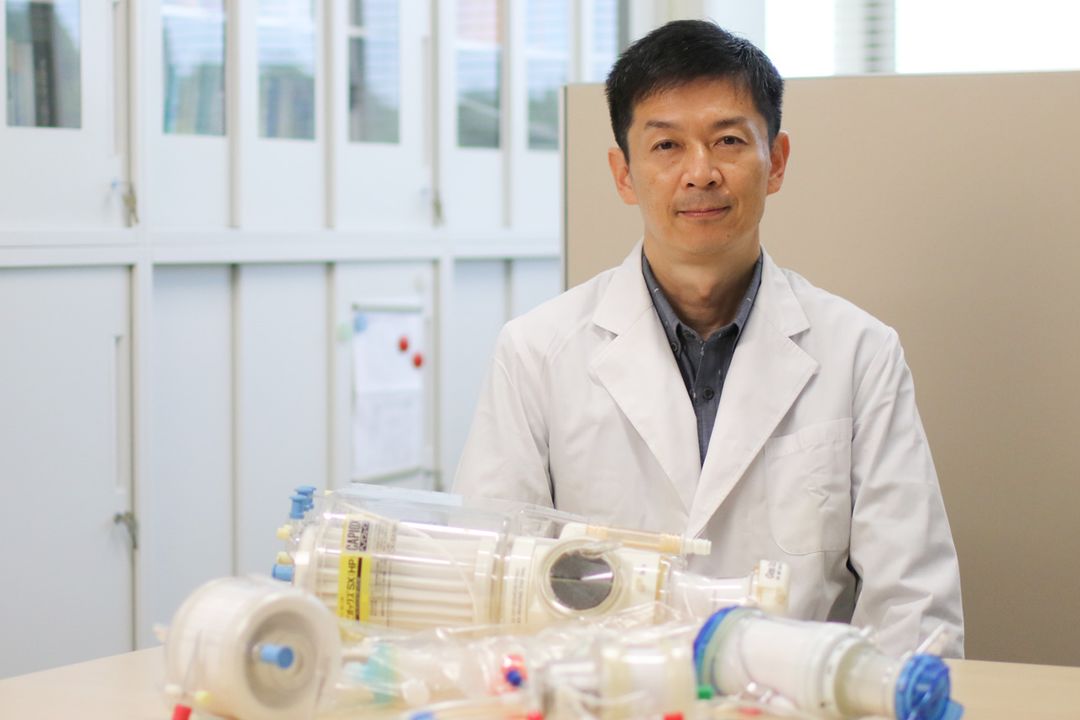

Our bodies’ numerous defense systems are constantly fighting off unwelcome organisms and objects to keep us healthy. But while these defenses are critical for our well-being, they pose major challenges for the scientists and doctors creating medical devices that save lives when our bodies need an outside assist.

“To avoid triggering an immune response and the creation of blood clots, most proteins and blood cells should not tightly adhere to any materials in devices that will come in contact with blood,” says Masaru Tanaka, professor of Kyushu University’s Institute for Materials Chemistry and Engineering.

Tanaka and his group are elucidating the molecular structures and mechanisms that make this possible to develop new biocompatible materials for medical devices. On top of uncovering new science for creating surfaces that interact with cells in novel, controlled ways, he is collaborating with doctors and industry partners to bring these advances to society.

Setting out to understand what gives certain materials their superb biocompatibility, Tanaka came across a common property they all share.

“Testing all the synthesized polymers used in medical devices approved for use in Japan along with many of the proteins, sugars, and DNA made by our bodies, we found that they all include of a layer of so-called intermediate water when immersed in water,” explains Tanaka.

Remarkably, in an environment full of extremely complex molecules, the simple water molecule plays a critical role in biocompatibility.

From a molecular point of view, Tanaka’s research categorizes water near material surfaces into three main groups. The crucial layer of intermediate water lies just between a layer of water that tightly attaches to the surface, known as “non-freezing water,” and the “free water” farther from the surface that can interact with both the surface itself and the water unaffected by the surface.

Though intermediate water is effectively invisible, Tanaka’s group has been able to identify its presence because it freezes at a different temperature than the other two types and also interacts differently with infrared radiation. The intermediate water appears to regulate how blood cells and proteins interact with and adhere to the surface.

However, this revelation only came after Tanaka had already helped develop biocompatible materials that inadvertently included this layer while working at a device maker before moving to academia.

“At the core of every great product is good, fundamental science, which in many cases will only be fully understood later. Understanding the science and theory at work then leads to new, better products,” says Tanaka.

While inclusion of intermediate water to prevent clotting is one crucial aspect of biocompatibility, achieving the adhesion of specific cells is also desired for opening numerous other medical applications. For example, stents and artificial blood vessels can benefit from their synthetic surfaces being covered by cells that line blood vessels.

Taking this to the next step, Tanaka and his group are also working to create materials to which cancer cells and stem cells selectively attach. Materials able to collect dilute cancer cells circulating in the blood after they break off from tumors would be promising for enabling earlier diagnosis of cancer. For regenerative medicine, Tanaka envisions many applications for materials that act as scaffolding for stem cells to help them develop into specific tissues or even organs.

“Medical practitioners, health care providers, and patients are constantly wanting better products. For this, the combination of fundamental research at universities and businesses’ ability to make products is essential,” says Tanaka.

Tanaka attributes his experience working on both sides of the problem to shaping his outlook and appreciation for research and product development and also to helping him collaborate with industry as he tries to bring innovations made in the lab to the public.

“With the ultimate goal of giving back to society and saving lives, we will continue research and education daily to make the invisible visible and understand the basic science of materials for future medical devices,” says Tanaka.