研究成果 Research Results

- TOP

- News

- Research Results

- Cutting-edge technology for mass production of highly formable Ni-based superalloy

Cutting-edge technology for mass production of highly formable Ni-based superalloy

2017.09.27Research ResultsMaterialsTechnology

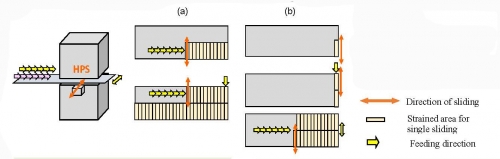

A research group of Prof. Zenji Horita of Kyushu University, in collaboration with Nagano Forging Co., Ltd. in Nagano city, has reported that it is now feasible to modify a hard-to-deform Ni-based superalloy (Inconel718) to be highly formable and to mass-produce for practical use. This new process involves straining under high pressure for microstructural modification and feeding every after the straining to extend to a large area of sheet as illustrated in Fig.1. This cutting-edge technology, now called incremental feeding high-pressure sliding (IF-HPS), no longer requires a further increase in the machine capacity so that it is possible to reduce the forming cost and increase the production efficiency. The Ni-based superalloy is well known because it has good heat and corrosion resistance for high-temperature use in air atmosphere. However, the formability of the alloy is very low so that it has been a long-time subject to overcome in practice.

The collaborating team of Kyushu University and Nagano Forging Co. has successfully demonstrated the importance of the new technology for cup forming as shown in Fig.2. The team has also demonstrated that the IF-HPS process is applicable not only for the Inconel718 superalloy but also for Ti alloys such as F1295, and therefore, it provides potential application for aerospace and biomedical industries as well as for automobile industry.

The collaborating project between Kyushu University and Nagano Forging Co. is currently ongoing under the support provided by the New Energy and Industrial Technology Development Organization (NEDO) / The Strategic Core Technology Advancement Program (FY2016-FY2018).

This research achievement was presented at IUMRS-ICAM 2017, the 15th International Conference on Advanced Materials on August 29, 2017

Fig.1

Illustration of IF-HPS to produce large areas of highly formable Ni-bases superalloy

(a)Extension in one dimension

(b)Extension in two dimensions

Fig.2

Unprocessed sample failed during cup forming.

Fig.3

Successful forming to cup shape for IF-HPS processed

Research-related inquiries

Zenji Horita, Professor, Faculty of Engineering/ WPI, International Institute for Carbon-Neutral Energy Research (WPI-I2CNER)

Yoichi Takizawa, Director, Technology Department, Nagano Forging Co., Ltd.

Yoichi Takizawa, Director, Technology Department, Nagano Forging Co., Ltd.

- TOP

- News

- Research Results

- Cutting-edge technology for mass production of highly formable Ni-based superalloy