研究成果 Research Results

- TOP

- News

- Research Results

- New ink jet approach offers simple way to print microdisk lasers for biosensing

New ink jet approach offers simple way to print microdisk lasers for biosensing

2021.02.09Research ResultsLife & HealthMaterialsTechnology

A new inkjet printing method can be used to fabricate tiny biocompatible polymer microdisk lasers for biosensing. The new approach allows fabrication in a room temperature, open-air environment.

Researchers have developed a unique inkjet printing method for fabricating tiny biocompatible polymer microdisk lasers for biosensing applications. The approach enables production of both the laser and sensor in a room temperature, open-air environment, potentially enabling new uses of biosensing technologies for health monitoring and disease diagnostics.

“The ability to use an inexpensive and portable commercial inkjet printer to fabricate a sensor in an ambient environment could make it possible to produce biosensors on-site as needed,” said research team leader Hiroaki Yoshioka from Kyushu University’s Faculty of Information Science and Electrical Engineering. “This could help make biosensing widespread even in economically disadvantaged countries and regions, where it could be used for simple biochemical tests, including those for pathogen detection.”

In The Optical Society (OSA) journal Optical Materials Express, the researchers describe the ability to print microdisk lasers as small as the diameter of a human hair from a specially developed polymer called FC-V-50. They also show that the microdisks can successfully be used for biosensing with the widely used biotin-avidin system.

“Our technique can be used to print on almost any substrate,” said Yoshioka. “This means that it could one day be possible to print a sensor for health monitoring directly on the surface of a person’s fingernail, for example.”

Eliminating the heat

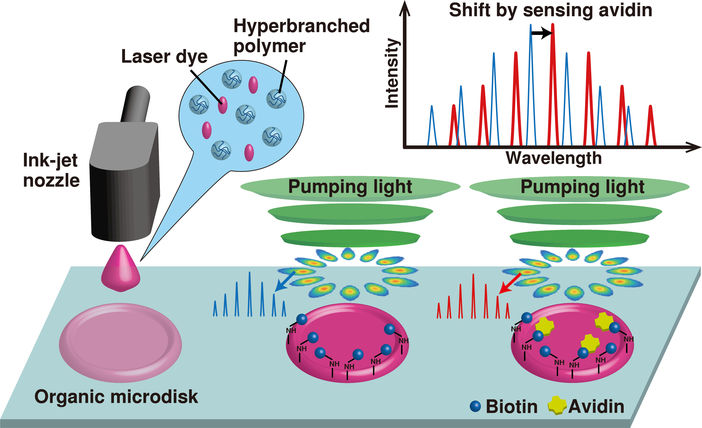

Many of today’s biosensors use the strong interaction between the molecules biotin and avidin to detect the presence of proteins that indicate infection or disease. This typically involves tagging a molecule of interest with biotin and then detecting when avidin binds to it.

One way to measure biotin-avidin binding is to add a biotin-labeled protein to the surface of an optical microcavity that acts like a miniature laser. When avidin binds to the biotin on the microcavity, its optical properties change enough to shift light emission in a way that can be used to detect binding.

However, the modification process needed to add biotin to the surface of microcavities is tedious and time-consuming. It also requires high-temperature heat treatments that aren’t compatible with all materials, such as polymers.

“We developed an organic microdisk optical cavity laser for biosensing using FC-V-50,” said Yoshioka. “This special inkjet polymer has a carboxyl functional group that is compatible with biotin, which eliminates the need for any type of heat treatment.”

Printing sensors

To produce microdisk lasers, the researchers developed an ink that contained FC-V-50 and a laser dye. A piezo element embedded in an inkjet nozzle about the size of a hair allows a single, tiny ink droplet to be ejected when a voltage is applied. Once dry, this printed drop will emit light when excitation light is applied. As the light travels along the inside circumference of the disk it is amplified to generate laser light.

To turn the microdisk laser into a sensor, the researchers printed a microdisk using their inkjet method and then added reagents that allowed biotin to immobilize on its surface at room temperature. They then used light to excite the microdisk laser under a microscope and measured the reference laser emission spectrum. Next, they poured the avidin solution onto the surface of the microdisk and washed away any that didn’t bind to the biotin. The laser emission was measured again to see how it deviated from the reference spectrum.

To test the method, the researchers fabricated biosensors and measured their ability to detect streptavidin protein at different concentrations. They were able to detect a maximum mode shift of 0.02 nanometers for a 0.1 parts per million concentration of streptavidin. Now that they have demonstrated the ability to print functioning biosensors, they plan to further evaluate and optimize sensor performance. Portable devices for measuring the light emission would also need to be developed for the sensors to be used at the point of care.

###

For more information about this research, see “Fully room temperature and label free biosensing based on an ink-jet printed polymer microdisk laser,” Abdul nasir, Yuaya Mikami, Rui yatabe, Hiroaki Yoshioka, Nilesh vasa, and Yuji Oki, Optical Materials Express 11, 592–602 (2021). https://doi.org/10.1364/OME.415000

This release is also available in Japanese.

Optical Materials Express

Optical Materials Express is an open-access journal focusing on the synthesis, processing and characterization of materials for applications in optics and photonics. It is published by The Optical Society (OSA) and emphasizes advances in novel optical materials, their properties, modeling, synthesis and fabrication techniques; how such materials contribute to novel optical behavior; and how they enable new or improved optical devices. The editor-in-chief is Alexandra Boltasseva from Purdue University, USA. Optical Materials Express is available online at OSA Publishing.

About The Optical Society

Founded in 1916, The Optical Society (OSA) is the leading professional organization for scientists, engineers, students and business leaders who fuel discoveries, shape real-life applications and accelerate achievements in the science of light. Through world-renowned publications, meetings and membership initiatives, OSA provides quality research, inspired interactions and dedicated resources for its extensive global network of optics and photonics experts. For more information, visit osa.org.

Provided by The Optical Society and edited for content and style.

Research-related inquiries

Hiroaki Yoshioka, Assistant Professor

Faculty of Information Science and Electrical Engineering

Contact information can also be found in the full release.

- TOP

- News

- Research Results

- New ink jet approach offers simple way to print microdisk lasers for biosensing