研究成果 Research Results

- TOP

- News

- Research Results

- New multistep mechanism for nanostructure formation found in liquid crystals

New multistep mechanism for nanostructure formation found in liquid crystals

Combination of molecular simulation and AI technologies making advances toward development of highly functional materials 2021.10.25Research ResultsPhysics & ChemistryMaterials

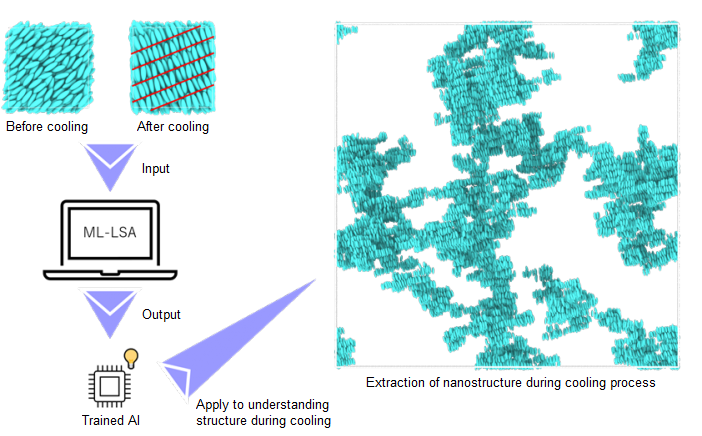

Researchers from Kyushu University and the National Institute of Advanced Industrial Science and Technology (AIST) have developed a novel analysis method that combines molecular simulation and artificial intelligence (AI) to observe the formation process of nanostructures in cooling liquid crystals. In doing so, they discovered a new three-step process of nanostructuring unexplainable by classical nucleation theory and also clarified its mechanism.

The team involved Senior Researcher Dr. Kazuaki Z. Takahashi and Principal Research Manager Dr. Takeshi Aoyagi of AIST and Professor Jun-ichi Fukuda of Kyushu University's Faculty of Science.

We interact with most of the commodities in our daily lives—from plastics and alloys to processed foods—as solids. However, these substances are often originally processed as liquids that are carefully controlled and cooled into their solid state. These liquid states can be composed of different materials such as liquid crystals, solutions, polymers, and biomaterials and, depending on the cooling processes, form a wide variety of structural patterns that can significantly influence the properties of solid products.

Therefore, understanding how the cooling process proceeds and how it can be controlled is vital in most scientific disciplines.

In many cases, the formation of a solid during the cooling process is initiated by the formation of nanostructures, which can be explained by classical nucleation theory. However, this theory cannot quantitatively account for some important physical properties such as the rate of nanostructure formation.

In an effort to accelerate the development of organic and polymeric functional materials through the fusion of computational science, process technology, and measurement technology, the New Energy and Industrial Technology Development Organization (NEDO), launched the "Ultra High-Throughput Design and Prototyping Technology for Ultra Advanced Materials Development Project."

One of the goals of the project is to develop technologies that control material structures, paying particular attention to nanostructuring and focusing on the cooling process of liquid crystals and typical organic and polymeric functional materials.

The research team explains that molecular simulations are promising as a technology to make possible the observation of previously unknown microscopic movement of individual molecules, the counting of nanostructures, and even the quantification of how structures increase.

However, there are still many kinds of nanostructures that are difficult to observe using molecular simulations alone, and the combination of molecular simulations with other advanced technologies is being envisaged to overcome this difficulty. It has thus been highly desired to develop computational technologies that provide new analysis methods for the identification of nanostructures with high accuracy.

In this study, the team applied AI technology to study structures obtained from molecular simulation during the cooling process and succeeded in extracting and observing the formation of nanostructures. What they found was that unlike in conventional classical nucleation theory—where nanostructures of various materials are formed through a one- to two-step process—liquid crystals would undergo a more complicated three-step process.

The team explains that this analysis technique can be applied not only to liquid crystals but also to polymers, biomaterials, and many other materials, and they hope that it can lead to the creation of a wide range of new highly functional materials.

###

For more information about this research, see “Multistep nucleation of anisotropic molecules,” Kazuaki Z. Takahashi, Takeshi Aoyagi, and Jun-ichi Fukuda, Nature Communications (2021). https://doi.org/10.1038/s41467-021-25586-4

Original press release can be found on the AIST website.

This release is also available in Japanese.

Research-related inquiries

Jun-ichi Fukuda, Professor

Department of Physics, Faculty of Science

Contact information can also be found in the full release.

- TOP

- News

- Research Results

- New multistep mechanism for nanostructure formation found in liquid crystals