研究成果 Research Results

- TOP

- News

- Research Results

- Investigating the role of greener plastics for Japan’s carbon neutral goals

Investigating the role of greener plastics for Japan’s carbon neutral goals

Japan’s plastic problem is a huge barrier to carbon neutrality. Could bioplastics and recycled plastics be the answer? 2023.09.26Research ResultsEnvironment & Sustainability

Fukuoka, Japan – Japan has a plastic problem. Thanks in part to an overabundance of packaging, the country is the second largest producer of plastic waste per capita.

While plastic pollution is a well-known cause for concern, an often-overlooked issue is how plastics contribute to global warming. Plastics are a surprisingly large cause of carbon emissions, with roughly 4.5% of global emissions caused by the plastics sector.

Now, joint research between Kyushu University and Yokohama-based start-up company, Sotas Co., Ltd, has investigated the potential for Japan’s market to incorporate a greener plastic supply chain.

“The Japanese government has pledged to achieve carbon neutrality by 2050. However, the predominant method that Japan uses to get rid of plastic waste is ‘thermal recycling’ or incineration, which releases carbon dioxide into the atmosphere,” says senior author Professor Andrew Chapman, from Kyushu University’s International Institute for Carbon Neutral Energy and Research. “We have examined whether switching to more sustainable recycled plastics and bioplastics is a competitive and effective alternative to current carbon reduction policies.”

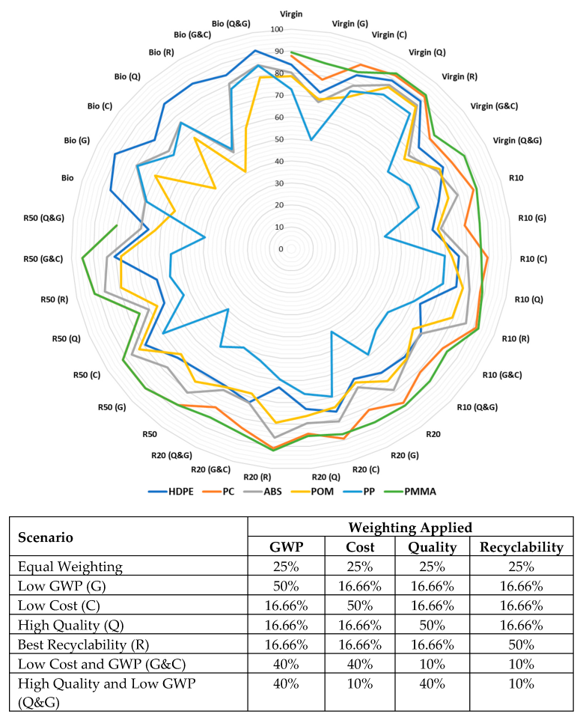

The researchers began with an economic and environmental assessment of six commonly used plastic types, based on whether they were made using virgin, recycled or bioplastic. They scored the plastics using four different criteria: global warming potential, cost, recyclability and perceived quality for manufacturers. Depending on the weighting given to each factor, the researchers calculated how desirable each plastic was under a number of scenarios.

Fig. 1. Multicriteria assessment of virgin, recycled and bioplastics for six different plastic types considering cost, emissions, perceived quality, and recyclability. The higher the points, the greater the desirability of the plastic to manufacturers.

In general, the researchers found that virgin plastics, which are made directly from fossil fuels, are perceived to be the highest quality, but have a high global warming potential and are relatively expensive.

Recycled plastics, on the other hand, are cheaper and also have a lower global warming potential. However, plastics with a higher blend of recycled material were perceived to be of lower quality and recyclability also varied greatly for each plastic type.

“One issue is that it can be physically harder to separate out some types of plastics before recycling and additionally, some plastics can only be recycled a certain number of times,” says first author Yuuki Yoshimoto, President of Sotas Co., Ltd. “It’s therefore important to establish a robust, centralized chain of custody to keep track of how many times a piece of plastic has been recycled to provide quality assurance to end users.”

The analysis also revealed that bioplastics, which are made from plants, have the lowest global warming potential. Some bioplastics can even be carbon-negative, as the plants take in carbon dioxide from the atmosphere as they grow, which is then sequestered in the material.

However, bioplastics are much more costly to make than virgin or recycled plastics, and, as drop-in replacements are not always available, currently perform less well regarding perceived quality. Additionally, starch-based bioplastics require arable land to grow the crops.

“Food versus plastic production is not a fight we want, as land resources are very limited in Japan,” says Prof Chapman. Instead, the researchers suggested further funding for research into cellulose-based bioplastics, which can be sourced from wood pulp.

One additional factor that could help bridge the gap in the cost between bioplastics and virgin plastics is the consumers’ willingness to pay. Prior research suggests that consumers are willing to pay more for environmentally-friendly products, which the researchers plan to investigate in detail and incorporate into their analysis.

“This is a complex situation, with no one-size-fits-all solution,” concludes Yoshimoto. “Ultimately we hope this analysis can help policymakers decide what recycling processes to support, and to inform manufacturers which plastics can best meet their manufacturing and carbon reduction goals.”

This research also considers the economic efficiency of carbon reduction via plastic recycling and bioplastic replacement, broadening the potential policy approaches which can be pursued by policymakers.

Fig. 2. Yuuki Yoshimoto, Representative Director and President of Sotas Co., Ltd. (left) and Professor Andrew Chapman (right) performing joint research in Kawasaki City.

###

For more information about this research, see "Toward Economically Efficient Carbon Reduction: Contrasting Greening Plastic Supply Chains with Alternative Energy Policy Approaches" Yuuki Yoshimoto, Koki Kishimoto, Kanchan Kumar Sen, Takako Mochida, Andrew Chapman, Sustainability, https://doi.org/10.3390/su151713229

Research-related inquiries

Andrew John Chapman, Associate Professor

International Institute for Carbon-Neutral Energy Research

Contact information can also be found in the full release.

- TOP

- News

- Research Results

- Investigating the role of greener plastics for Japan’s carbon neutral goals